Preparing Ribbed Smoke sheets - RSS rubber

Introduction

Natural rubber latex is traditionally converted into sheet form through careful coagulation and subsequent milling

process on two roll mills. There are many types of sheets rubbers namely Ribbed smoked sheet rubber, Air dried sheet

tuber and sun dried sheet rubber depending on the drying methodology used. Among them, Ribbed Smoked Sheet (RSS) has

been the major form of raw rubber produced in Sri Lanka (above 40%). Practically entire volume of this grade of rubber

is produced by small and medium scale rubber growers who own below 10 acres and between 10-50 acres respectively,

scattered in the rubber growing districts in the country. This is mainly due to the simplicity and low cost of the

processing machinery, easily adoptable processing technology, and the viability of the manufacturing process with any

amount of latex.

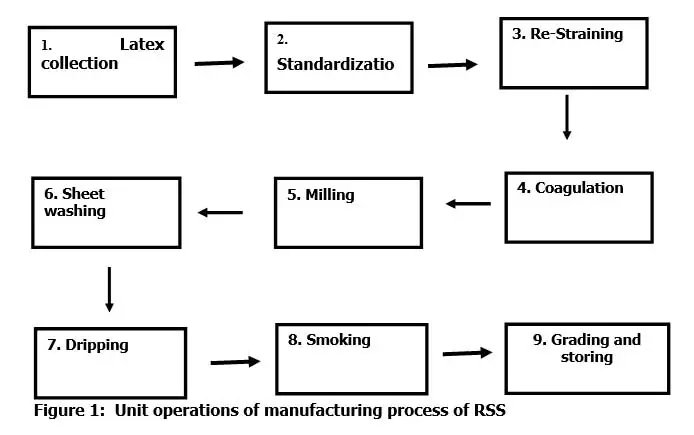

Let us see the unit operations of manufacturing process of RSS which is given below.

Latex collection

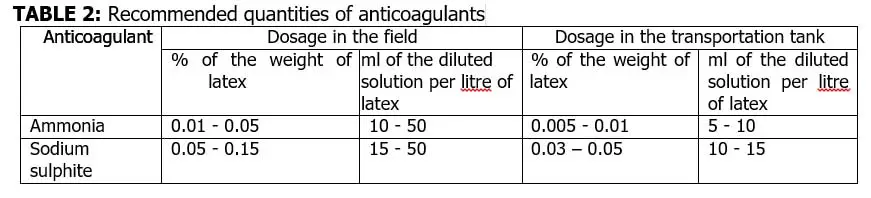

Conventionally, cleaned coconut shells are used for the collection of latex from rubber trees. However, cups made out of plastic or thermoplastic natural rubber (TPNR) cups introduced by Rubber Research Institute of Sri Lanka are now recommended for this purpose. Contamination with foreign materials such as tree barks, sand particles and rain water should be completely avoided. If there is a tendency for pre-coagulation of latex, anti-coagulants (ammonia as 1% solution or sodium sulphite as 3% solution) should be added into the latex in the field. Quantities to be used are given below.

The latex should be subjected to a preliminary straining through a sieve fitted with Monel gauze of 40-50 mesh or stainless steel mesh. For this purpose, brass mesh is not recommended since minute traces of copper can affect the quality of the rubber. Rubber Research Institute has reported that a copper content above 5ppm causes the degradation of Natural rubber molecules. All the precautions should be taken to avoid pre-coagulation of latex and to minimize the foreign material contamination of latex.

Standardization of latex

Dry rubber content (DRC) of latex should be brought down to a standard DRC by diluting the latex with clean and pure water prior to addition of acid for coagulation. The recommended standard DRC to be used in RSS manufacture is 12.5%. Dilution water should always be strained off through a fine cloth. Dilution helps in achieving quality consistency of the final product. It also gives a softer coagulum which can be easily be sheeted. Dilution also assists in faster settling of dirt, improving the clarity of the sheets, bringing down the viscosity of the latex thus distributing the chemicals added to the latex (acids) more uniformly and escaping trapped air and any fomentation gases from the latex more easily.

Latex from some old clones darkens final RSS sheet due to enzymatic discoloration. If this discoloration is experienced, a sufficient quantity of sodium metabisulphite or sodium bisulphate should be added as 3% (w/w) solution (maximum recommended dose: 50 g/100 kg of dry rubber).

Re-straining

As in the step 1, bulked latex should be re-strained through a sieve fitted with Monel gauge of 40-50 mesh or stainless steel mesh in to clean latex coagulating vessels (pans or DCL tanks) to remove any foreign materials which are added to latex during the standardization process.

Coagulation

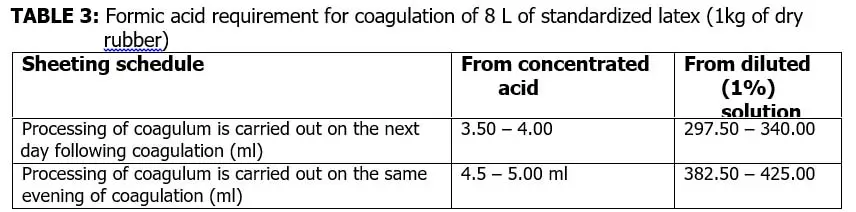

For latex coagulation, formic acid is widely used. However, acetic acid could also be used for same purpose. They are added into coagulation pans or DCL tanks filled with diluted latex. formic acid is added to the already diluted latex as 1 % diluted formic acid as given below.

Addition of acids in diluted form assists in achieving uniform distribution of acids in latex and thereby complete coagulation and in getting a soft coagulum to produce sheets free from air bubbles and stickiness. After adding the acid solution, the latex should be mixed thoroughly using an aluminium sheet or a wooden plate and the resulting froth should be skimmed off by means of a suitable skimmer such as a piece of smooth board or aluminium or galvanized iron sheet to prevent the formation of pitting of the surface of the dried sheets. Coagulation pans or DCL tanks then should be covered properly and placed horizontally. They should be kept undisturbed for adequate period for completion of the coagulation process. This step is very important to prevent falling any foreign particles (insects, flies and any dirt particles) on to the coagulum and to facilitate getting a sheet with even thickness and uniform weight.

Milling of coagulum

After draining out the serum, the coagulum is placed on a cleaned horizontal table or an aluminium plate and hand pressed to make a uniform thickness sheet. It is important to make sure that no thick edges are formed during hand pressing. This operation makes easier to work on the two roll mills to get a even thickness sheet and to wash out the serum substances. The hand pressed coagulum is rolled on the pre-cleaned smooth rollers two to three times, the space between the rollers being reduced after each milling, and is then passed through the marking (diamond) roller to thin down the coagulum to in sheet form with even thickness (3.2 mm). The rollers should be fitted with a water spray so that the serum is washed off the sheet as it is squeezed out. A battery consist of three to four pairs of smooth rollers and one pair of spirally grooved rollers mounted as a unit could be used for the milling purpose (preferably for medium and large scale producers).

Washing of sheets

The freshly sheeted sheets should be soaked in running water for a short time after milling to wash off the residual non-rubbers and, to prevent discoloration and mould growth of sheets during next step ie. dripping period.

Dripping

Milled sheets are hung up to drip off the remaining water for four to six hours preferably in a draft in the shade to drain off the surface moisture and thereby reduce the smoking period. After dripping, sheets either can be smoked straight away using a smoke house or it can be sun dried for about two days before loading into the smoked house.

Smoking

Dripped sheets which contain about 20 per cent moisture are dried in a smoke house. Smoking of sheets has definite advantages in addition to drying of sheets. Smoking enables the sheets to absorb creosotic and other antiseptic substances which provide a preservative effect and anti-oxidant effect on to the rubber. Smoke house should be heated under moderate fire with a low level of smoke and this will lead to produce sheets with a good appearance. Temperature of the smoke house should be maintained at correct range between 48-54 oC. Sheets should be turned over daily during the smoking to prevent any marks on the sheets, commonly known as reeper marks. Generally, smoking could be completed within 4-5 days.

It has been recently shown that sun drying of sheet rubber for three to four days for complete dryness will not adversely affect the physical or vulcanizate properties of the rubber, but in order to eliminate mould contamination of the sheet rubber, smoking in a smoke house for one to two days is recommended. In addition, recent experiments carried out on uninterrupted smoke drying of sheet rubber after 6-8 hours dripping under sun in well insulated drying chambers with a layer of gravel bed has suggested that sheets could be smoke dried in a single day provided that sheets are manufactured according to the recommended manufacturing procedures to meet the standard specifications (Thickness: 3.2 mm and weight: 450-550g). Same study has also shown that maintenance of drying temperature at a higher range of 60 to 650C is possible as the technical properties of the sheets are not adversely affected when dried within this temperature range .

Grading and storing

Smoked sheets are visually examined by holding them against clear light to inspect any speck and impurities remaining inside. Sheets are sorted into six grades namely No. 1XRSS, 1RSS, 2RSS, 3RSS, 4RSS and 5RSS on the basis of colour, translucency, presence of mould, bubbles dirt etc. However, it should be mentioned that no master or international sample has been established for theses grades. Sheets should be stored in a dry place with good ventilation.

Is ribbed smoke sheets are valuble than crepe rubber sheets?

Manufacturing process of ribbed smoke sheets is not complex like manufacturing process of crepe rubber. Crepe rubber production consumes lot of water and other sources like electricity. Therefore crepe rubber are more valuble than ribbed smoke sheets.

Differences between crepe rubber sheets and ribbed smoke sheets?

Crepe rubber sheets are white colour. But ribbed smoke sheets are yellow colour due to presence of proteinaceous substance. In crepe rubber sheets, those proteinaceous substances are removed by washing.